Yamaha SMT Mounters: High-Speed PCB Assembly Solutions

As industry-leading solutions for precision surface mount technology, Yamaha SMT mounters deliver unmatched speed and accuracy for modern PCB production lines. Our range of Yamaha SMT mounters, including the YSM10, YSM20, and flagship YSM40R models, are engineered to meet the rigorous demands of high-volume electronics manufacturing while maintaining micron-level placement precision.

The YSM10 model sets the standard for entry-level production with a robust 42,000 chips per hour placement rate and ±28μm accuracy, while the YSM20 boosts productivity to 78,000 CPH with enhanced ±25μm precision. For mission-critical applications, the YSM40R achieves an exceptional 126,000 CPH with ±15μm accuracy – the tightest tolerance in its class – making it ideal for advanced microelectronics and automotive-grade components.

At the heart of Yamaha’s mounting technology lies the revolutionary PDPA (Position Decision Parallel Algorithm) vision system, which combines high-speed imaging with real-time component analysis to achieve 25μm recognition accuracy in just 0.08 seconds per component. This advanced vision technology, combined with multi-function placement heads, enables simultaneous pick, place, and rotate operations with six-sensor feedback control for flawless component orientation.

Our Yamaha mounters excel in handling the most challenging micro-components, including miniature 01005 chips measuring just 0.4×0.2mm and ultra-fine pitch micro-BGAs with 0.3mm spacing. The intelligent vacuum-force control system automatically adjusts suction pressure based on component weight and fragility, while the four-angle inspection system verifies ball grid alignment before placement.

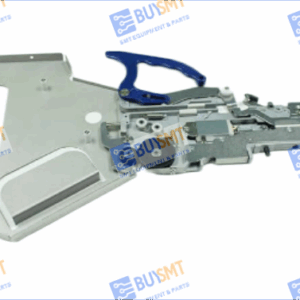

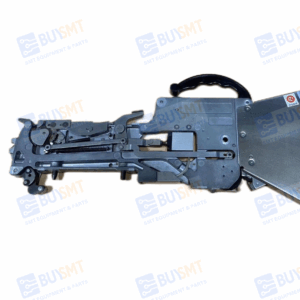

For seamless production line integration, all Yamaha SMT mounters feature SMEMA-compliant conveyor interfaces with automatic width adjustment from 50mm to 500mm, eliminating manual configuration between board changes. The RFID-enabled feeder recognition system instantly identifies connected ZS, CL, and HS feeders, while the comprehensive calibration sequence ensures optimal performance through machine leveling (maintaining 0.05° tolerance), vision offset compensation, nozzle center-point mapping, and PDPA algorithm training.

Every Yamaha mounter we supply undergoes rigorous performance validation using JIS-B-9751 standards, consistently achieving over 98.5% first-pass yield in demanding automotive electronics applications. This commitment to quality assurance ensures your production line maintains maximum uptime while meeting the most stringent quality requirements.

Key Features:

- Precision Placement: ±15μm accuracy on YSM40R model

- High-Speed Operation: Up to 126,000 CPH throughput

- Micro-Component Capability: Handles 01005 chips and 0.3mm pitch BGAs

- Smart Integration: RFID feeder recognition and auto-width conveyors

- Quality Assurance: JIS-B-9751 validated performance