Évitez les erreurs de prélèvement, les temps d'arrêt et les erreurs de l'opérateur en apprenant la bonne façon de charger votre margeur SMT Fuji. Ce guide vous guidera à travers chaque étape de manière claire et professionnelle.

Qu'est-ce qu'un alimentateur SMT Fuji et pourquoi un chargement correct est-il important ?

Les Alimentateur SMT Fuji est un composant essentiel d'une ligne de production SMT, conçu pour alimenter les composants à partir de rubans porteurs dans la position de prise d'une machine de placement. Un chargement incorrect peut entraîner des erreurs de prélèvement et d'alignement, voire l'arrêt de la machine, ce qui affecte directement l'efficacité de la production.

✅ Les avantages d'un chargement correct des chargeurs :

- Improved placement accuracy and stability

- Réduction des taux d'erreur et des reprises

- Moins d'usure de vos machines

- Un fonctionnement plus rapide et plus sûr

Modèles courants d'alimentateurs Fuji

Avant de commencer, assurez-vous de connaître votre type de chargeur. Les modèles de margeurs Fuji suivants sont les plus courants. Ils sont tous disponibles sur notre site avec des spécifications et des prix détaillés :

- Alimentateurs Fuji de la série NXT

- Alimentateurs Fuji CP6 / CP642 / CP643

- Série AIMEX

- Série XP

🔍 Remarque : les modèles d'alimentateurs varient en fonction de la compatibilité de la machine - vérifiez soigneusement avant d'acheter.

Ce dont vous aurez besoin avant le chargement

Préparez les outils et matériaux suivants avant de charger votre chargeur Fuji :

- Chargeur Fuji compatible

- Bande de support de composant

- Machine de placement SMT (par exemple Fuji Pick and Place)

- Gants ESD

- Support d'alimentation (en option)

7 étapes pour charger correctement un chargeur SMT Fuji

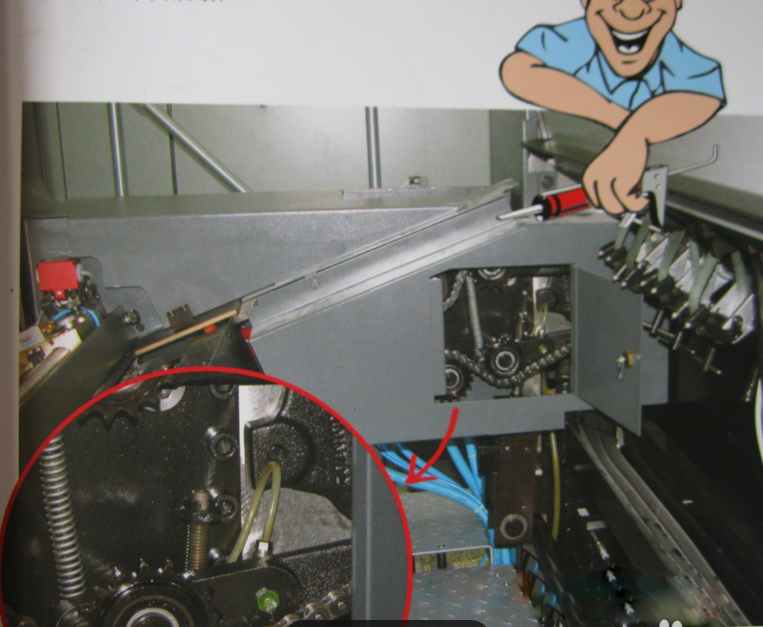

Étape 1 : Inspection de l'alimentateur

- Assurez-vous que l'alimentateur est propre et en bon état.

- Porter des gants ESD pour éviter les dommages dus à l'électricité statique

Étape 2 : Insérer la bande

- Monter le rouleau de bande sur le porte-bobine arrière du chargeur.

- Introduire la bande dans la fente d'entrée le long de la piste d'alimentation.

Étape 3 : Alignement des trous de pignon

- Veillez à ce que les trous du ruban soient parfaitement alignés avec les dents du pignon.

- Tourner manuellement la roue pour vérifier que l'alimentation se fait sans heurts.

Étape 4 : Fixer le ruban de recouvrement

- Décoller la bande de protection et la fixer sur la bobine d'enroulement.

- Veillez à ce qu'il s'enroule facilement et ne s'entortille pas.

Étape 5 : Test de l'alimentation manuelle

- Appuyer sur le bouton d'alimentation manuelle

- Le premier composant doit s'aligner correctement sur le point de prélèvement.

Étape 6 : Montage de l'alimentateur

- Faites glisser le chargeur dans son emplacement sur la machine pick-and-place.

- Écoutez le "clic" qui confirme que l'appareil est sécurisé.

Étape 7 : Confirmation de l'installation dans le logiciel

- Utiliser l'interface machine pour assigner la position du chargeur et l'identification de la pièce

- Exécuter un test de prélèvement pour vérifier la fonctionnalité

| Enjeu | Cause possible | Solution |

|---|---|---|

| Décalage du pick-up | La bande de couverture n'a pas été entièrement retirée | Vérifier et rembobiner correctement la bande |

| Chute des composants | Tension de bande relâchée ou bande usée | Ajuster la tension ou remplacer la bande |

| L'alimentateur n'est pas reconnu | Montage incorrect | Réinsérer l'alimentateur et vérifier la connexion |

Besoin de mangeoires de remplacement ? Parcourez notre Catalogue des produits SMT Feeder pour connaître les options compatibles et demander un devis.

Ressources connexes

- 🔧 Machines Pick and Place de Fuji

- 🔩 Chargeurs Yamaha SMT (Comparez avec Fuji)

- 📦 Tous les modèles et marques de chargeurs SMT

Réflexions finales : Chargement standardisé = production efficace

Apprendre à charger correctement un chargeur Fuji SMT est la base d'une fabrication SMT cohérente. En suivant les étapes ci-dessus, vous réduirez les temps d'arrêt de la machine et améliorerez la qualité du produit.

Si vous êtes à la recherche de margeurs Fuji fiables et compatibles, consultez nos Fuji SMT Feeder category page. Nous proposons des services d'expédition à l'échelle mondiale et une assistance professionnelle.

✅ Prêt à améliorer votre ligne ? Visitez notre SMT Feeder collection now pour des systèmes d'alimentation performants.