For a qualified sales and technical engineer, understanding SMT production line configuration is essential. SMT (Surface Mount Technology) involves complex systems engineering, strong technical demands, significant investment, and associated risks. Choosing the right combination of SMT production equipment from a wide range of brands and models based on customer needs is a relatively challenging and intricate task.

Although I’m not a sales engineer myself, I have some basic knowledge of the subject. By combining practical experience and research, I’ve compiled a brief summary to outline: What equipment is involved in a complete SMT production line? How should it be configured? And what configuration schemes can be adopted?

I. What Equipment Makes Up the SMT Production Line Process?

A complete SMT production line typically includes the following equipment:

Loader → Automatic Solder Paste Printer → Online SPI (Solder Paste Inspection) → SMT Pick and Place Machine → Online AOI (Automated Optical Inspection) → Reflow Oven or Wave Soldering → Online AOI → X-ray Inspection → Unloader

In addition to the above, there are also buffer conveyors, cleaning machines, and other auxiliary units between each major machine. These components together form a full SMT production line.

Important note for SMT manufacturers: A complete SMT line consists of various machines with different processing roles. The overall efficiency of the line is not determined by the fastest machine, but by the slowest one. If one piece of equipment runs slower than the rest, it becomes the bottleneck and limits the throughput of the entire line.

II. What Are the Configuration Plans for SMT Production Lines?

As electronic products become more refined, electronic components are also becoming smaller and more integrated. The widespread use of 0201, 01005 components, and ICs with pin pitches below 0.4mm demands ever-increasing precision and performance. Therefore, configuring a high-precision and high-quality SMT line is becoming increasingly important.

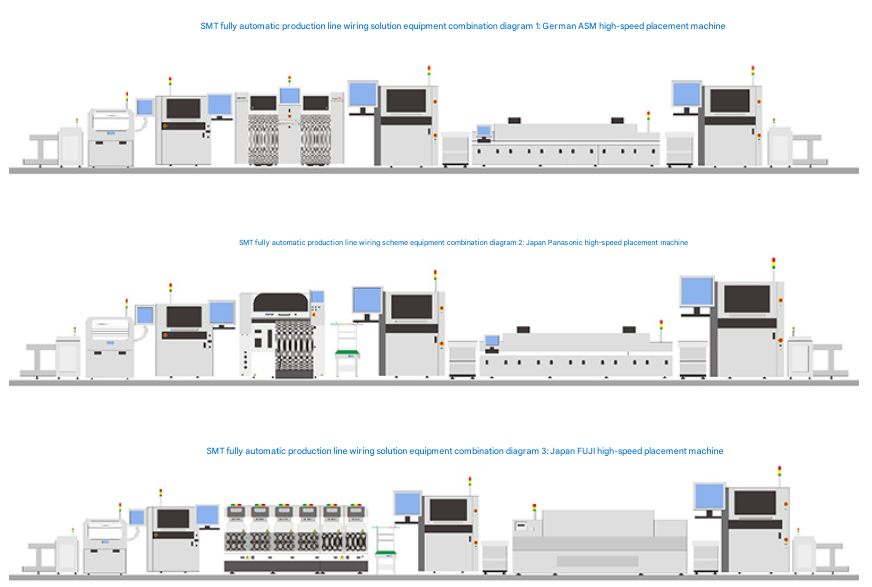

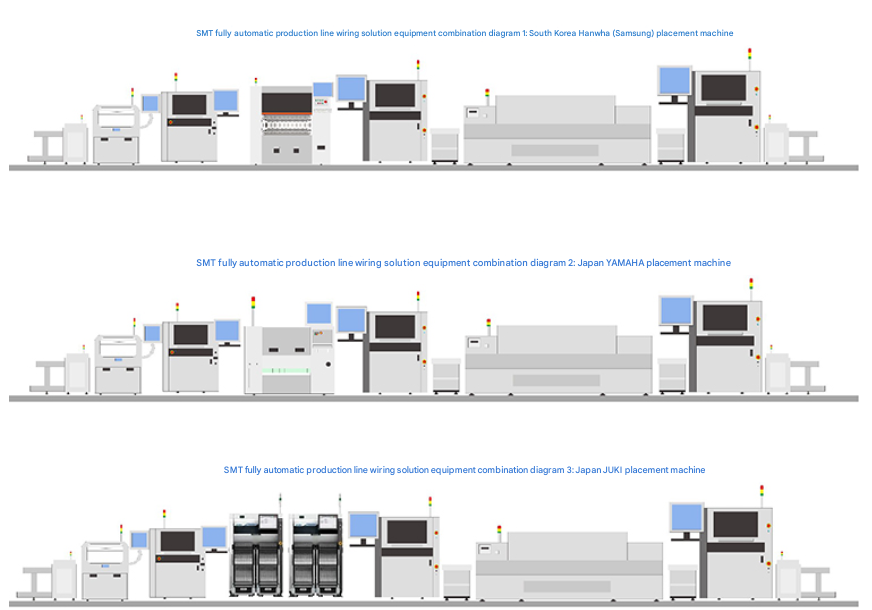

Since there are many types of equipment in an SMT line, let’s take the core machine — the SMT pick-and-place machine — as an example to show a few configuration schemes:

1. High-Speed SMT Placement Line Configuration

2. Medium-Speed SMT Placement Line Configuration

Note: The diagrams shown are not complete or optimized production lines — they are simplified examples for layout reference only and should not be directly applied. The technical parameters of each machine in the line must be matched appropriately. Otherwise, even with high-end equipment, mismatched configurations will result in wasted resources and increased operational costs.

If you happen to need it, we happen to specialize in it.

buysmt provides one-stop SMT production line solutions tailored to your needs. Feel free to contact us for professional consultation!