Introduction: Why Choose Used Equipment for Your SMT Line?

Setting up a new SMT (Surface Mount Technology) production line can be expensive—but used equipment offers a cost-effective solution without compromising quality. With proper planning, reliable suppliers, and strategic configuration, you can reduce startup costs by 30–60% while maintaining performance and reliability.

🛠️ 1. Define Your Production Needs

Before investing, assess:

- Production Volume: Low, medium, or high throughput?

- Product Type: Simple consumer electronics or complex automotive PCBs?

- Component Range: 0402 chips, BGA, QFN, etc.

- Future Scalability: Can your line scale up as business grows?

These factors determine what type and how many machines you need.

🔧 2. Core Equipment Selection

▶️ A. Pick and Place Machines

This is the heart of any SMT line. Choose based on:

| Type | Description | CPH Range | Example Brands |

|---|---|---|---|

| High-Speed Chip Shooter | Optimized for passive components | 20K–100K | Fuji NXT, Yamaha YS |

| Flexible Placer | Handles ICs & odd shapes | 6K–40K | Juki KE, Samsung SM |

✅ Used Pick and Place Machines are ideal for startups with limited capital.

▶️ B. Solder Paste Printer

Accuracy in paste deposition is key. Options:

- Semi-auto printers: Suitable for low-volume lines

- Fully automatic: For precision and speed

▶️ C. Reflow Oven

Choose based on:

- Number of heating zones (e.g., 6–10 zones)

- Conveyor speed and width

- Brands: Heller, Rehm, JT

▶️ D. Inspection Equipment

- AOI (Automated Optical Inspection): Detects soldering and component issues

- X-Ray: For BGA/QFN hidden joint verification

▶️ E. Auxiliary Equipment

- PCB loader/unloader

- Conveyor systems

- ESD-safe working stations

💰 3. Cost Optimization Strategy

📊 TCO: Total Cost of Ownership = Initial + Operating + Maintenance Costs

| Type | Approx. Used Price (USD) |

|---|---|

| Pick and Place (mid-range) | $15,000–$45,000 |

| Reflow Oven | $10,000–$30,000 |

| Printer | $3,000–$10,000 |

| AOI/X-ray | $8,000–$25,000 |

| Full Line Setup | $50,000–$130,000 (basic); up to $500,000 (advanced) |

Tips:

- Choose tested and warranted used equipment.

- Invest in spare parts like nozzles and feeders early.

- Buy from verified suppliers with service history.

🧩 4. SMT Line Layout Planning

- Straight-Line or U-shaped layout for space efficiency

- Maintain clear access for operator movement

- Ensure smooth PCB transfer between stages

- Minimize bottlenecks between inspection and placement

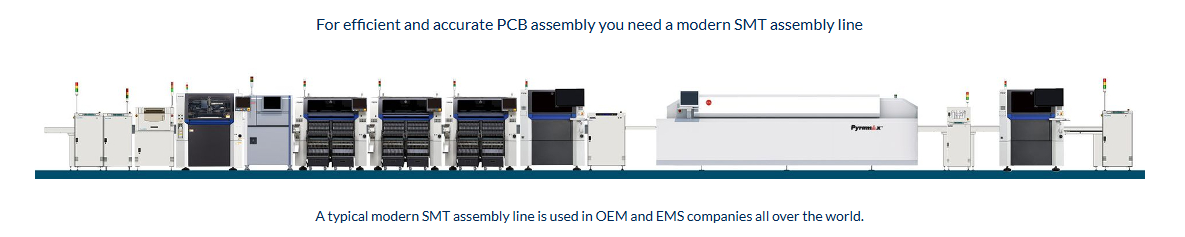

🖼️ Visual layout diagrams can further improve planning accuracy.

🔧 5. Operation and Maintenance

- Schedule preventive maintenance monthly

- Keep key spare parts (nozzles, sensors, belts) in stock

- Monitor placement accuracy and yield data

- Use training videos/manuals for staff efficiency

🛠️ Explore our Feeder Maintenance Guide for details.

🤝 6. Why BUYSMT?

At BUYSMT, we provide:

- ✅ Fully tested used SMT equipment

- ✅ Spare parts like nozzles, feeders, sensors

- ✅ Video demo & live inspection service

- ✅ Custom production line configuration advice

📩 Contact us now to get a free quote or SMT setup proposal.