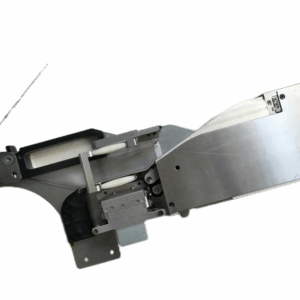

Looking for a reliable SMT feeder to keep your PCB assembly line running at peak efficiency? Our precision feeders hold, align, and deliver resistors, capacitors, integrated circuits, and more into automated pick‑and‑place machines minimizing placement errors and reducing downtime. Explore our industry‑leading range to boost throughput, maintain consistent quality, and meet the tightest assembly tolerances on your printed circuit boards.

KaiFeng Park

2nd Floor,Bao'an , SZ

Phone Number

(+86)181 7910 9874