What is Surface Mount Technology (SMT)?

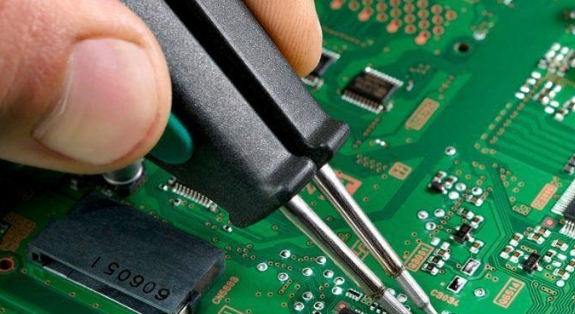

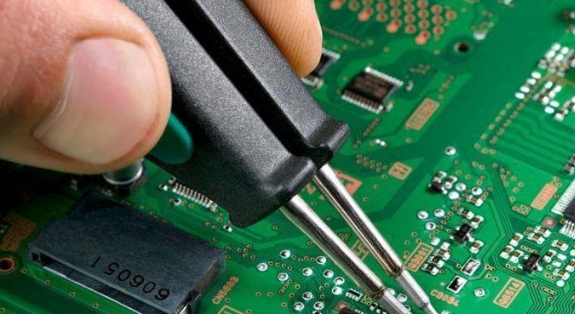

Surface Mount Technology (SMT) is a method in electronics manufacturing in which electronic components — known as Surface Mount Devices (SMDs) — are mounted directly onto the surface of Printed Circuit Boards (PCBs). SMT has become the dominant assembly technology due to its efficiency, automation compatibility, and support for miniaturization.

SMT vs. Through-Hole Technology

Unlike Through-Hole Technology (THT), where leads are inserted through drilled holes in the PCB, SMT mounts components directly on the surface. This eliminates the need for drilling, increases assembly speed, and allows components to be placed on both sides of the board.

SMT Manufacturing Process Overview

1. SMD and PCB Preparation

- Design of surface-mounted pad layout

- PCB copper pad preparation (typically gold or silver-plated)

- Material quality inspection and stencil preparation

2. Solder Paste Printing

- Solder paste applied using a stencil printer and metal squeegee

- Paste is a mixture of solder powder and flux for bonding

👉 Browse SMT Stencil Printers »

3. Component Placement

- Pick-and-place machines use vacuum nozzles to position SMDs

- Capable of placing up to 80,000 components per hour

👉 Used Pick and Place Machines »

4. Reflow Soldering

- PCBs pass through thermal zones: preheat, soak, reflow, and cooling

- Solder melts and creates electrical connections between pads and leads

5. Cleaning and Inspection

- Flux residue and impurities are cleaned post-reflow

- Inspection via AOI, X-ray, and flying probe testing

👉 Check SMT Cleaning Solutions »

Benefits and Challenges of SMT

| Benefits | Challenges |

|---|---|

| Supports component miniaturization | Requires precise soldering and handling |

| Enables full automation and high throughput | Higher investment in advanced machinery |

| Reduces board size and weight | Difficult rework due to small component sizes |

| Lowers overall production costs | Needs expert training and maintenance |

| Enhances performance and reliability | Inspection is more complex |

Understanding SMT vs. SMD

- SMT (Surface Mount Technology): The process used to place and solder components directly on a PCB.

- SMD (Surface Mount Device): The actual electronic component used in SMT, such as resistors, capacitors, and ICs.

👉 Browse SMT Nozzles & Spare Parts »

Applications of SMT

SMT is widely used in:

- Consumer Electronics (smartphones, tablets, TVs)

- Automotive Electronics (ECUs, sensors, infotainment)

- Medical Devices (monitors, diagnostic tools)

- Industrial Automation (control systems, PLCs)

At BUYSMT, we provide comprehensive SMT line solutions, including:

- Stencil Printers »

- Pick and Place Machines »

- Reflow and Wave Soldering Machines »

- SMT Cleaning Agents »

- Nozzles, Feeders, and Spare Parts »

Surface Mount Technology revolutionized the electronics assembly industry, enabling miniaturized, lightweight, and high-performance PCBs. As electronics continue to evolve, SMT remains essential for scalable, high-quality production.

BUYSMT is your global partner for turnkey SMT line solutions and premium used SMT equipment. We offer a large inventory of machines, spare parts, and technical support tailored to your production needs.

BUYSMT® – Trusted Global Supplier of SMT Equipment and Parts

🌐 Website: www.buysmt.com

📩 Email: sales@buysmt.com / info@buysmt.com

📲 WhatsApp: +86-18179109874