一、 载具与夹具的使用场景

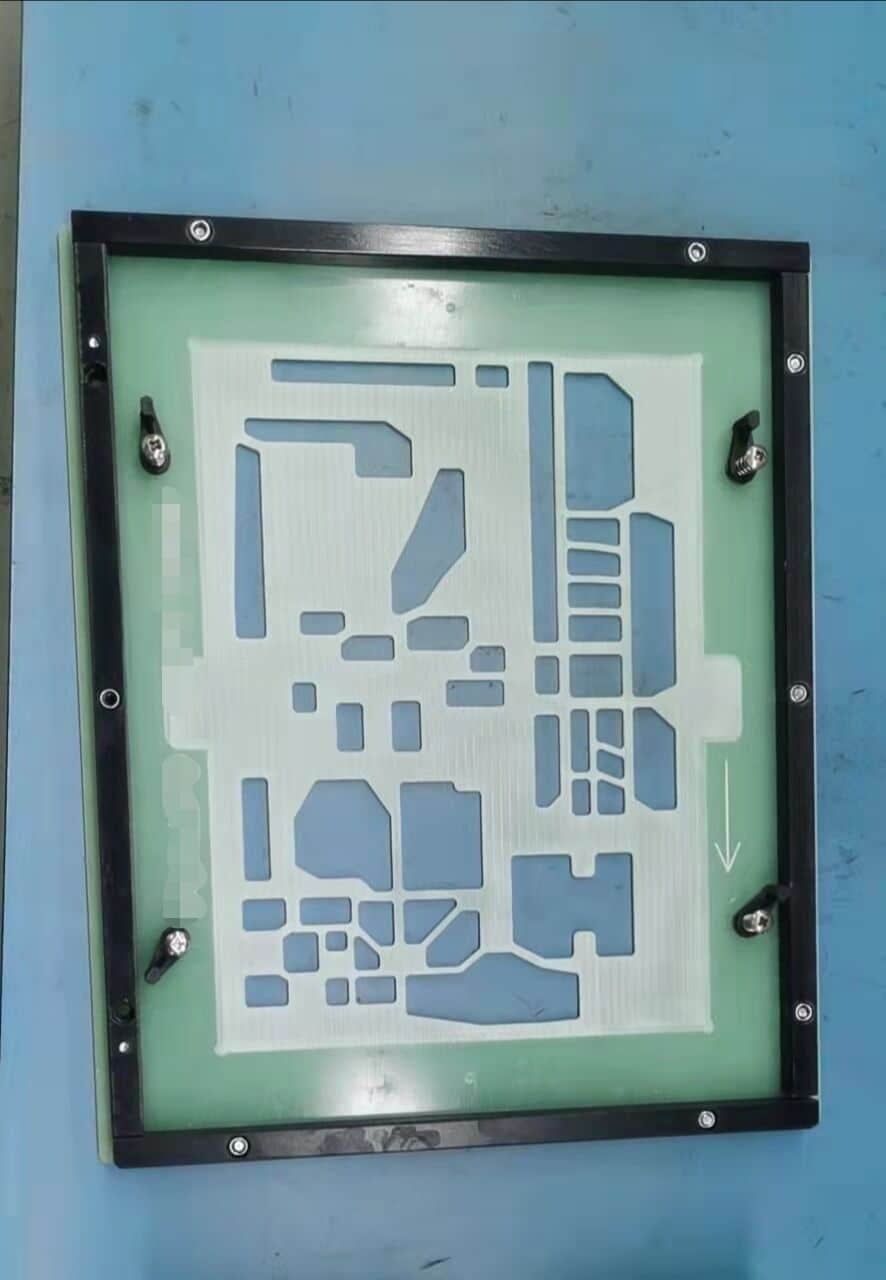

载具: 主要是在印刷及贴片机贴装时,辅助生产使用。0.8mm以上的如拼板不合理会断板也需要使用。

使用场景

1.PCB板薄: PCB板厚在0.4mm、 0.6mm、 0.8mm时 需要有载具托着PCB板进行印刷和贴片。全自动印刷机同样需要一定的支撑力保持与钢网共面并贴合,贴片机贴装时更需要PCB保持平行共面性,来确保贴装精度。 薄板在过回流焊时同样由于高温PCB容易弯曲变形而掉出轨道。

2.双面贴片: 双面贴片,如双面都有较重器件或较为密集排布时,为保证各工序生产质量均需用载具。

3.贴片器件伸出PCB板: 如有贴片的器件伸出PCB板外,元器件重心不在板面或在工艺边无法保证轨道正常运输,会在移动的过程中不稳而偏移掉落,仍需要用到载具。

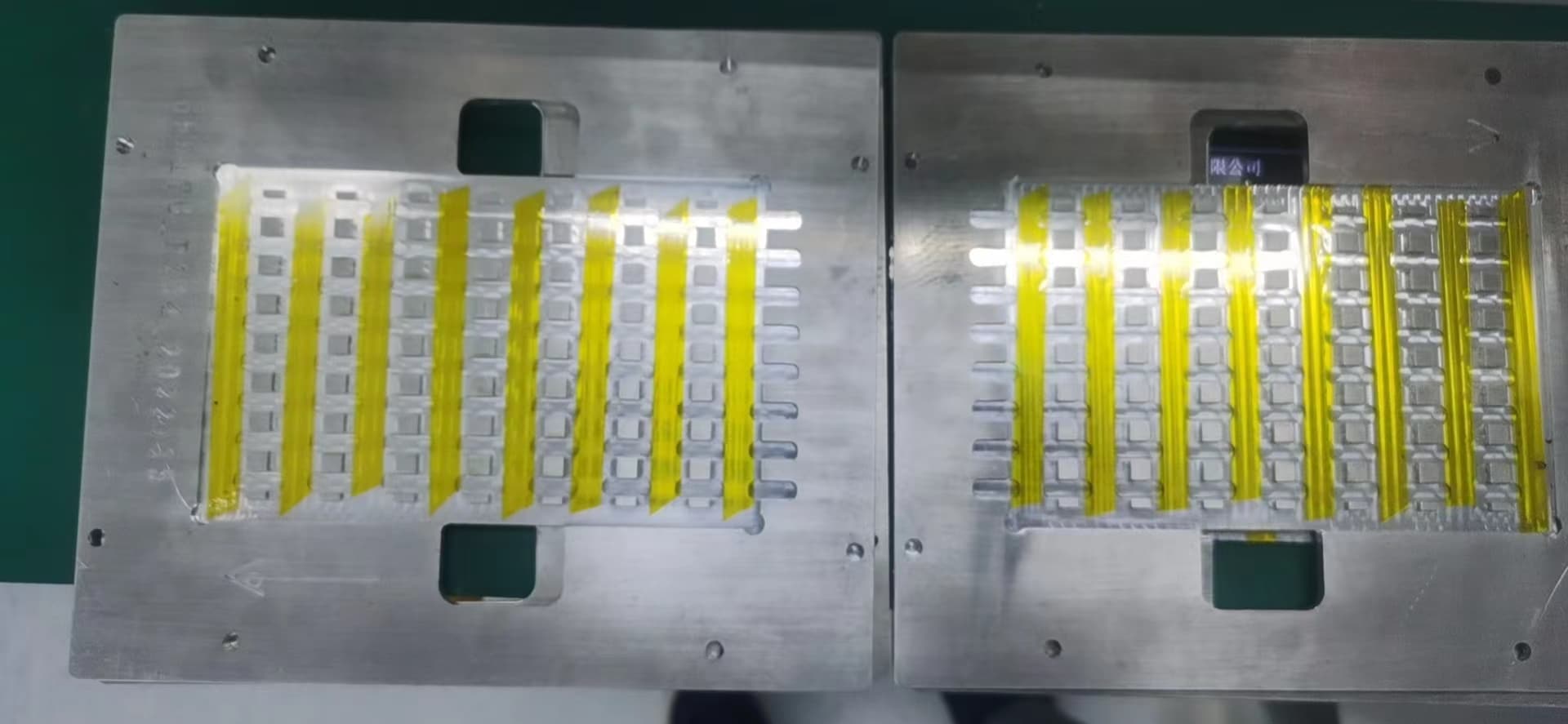

夹具: 主要是在插件波峰焊时使用。辅助焊接使用。

使用场景

1.PCB板薄: PCB板厚在0.4mm、0.6mm,需要有载具托着PCB板过波峰焊。波峰焊轨道对较薄的板不能定位加紧且易变形造成焊接不良,同样由于温度影响弯曲掉入锡炉而报废产品。

2.双面焊接:插件的焊接面有过回流焊焊接好的锡膏板,为防止贴片好的器件掉落到锡炉里面,需要用夹具保护贴片器件。

3.插件伸出板外,如有插装的器件伸出PCB板外,元器件重心不在板面或在工艺边无法保证轨道正常运输,为防止器件在波峰焊接的时偏移或掉落,需要有用到夹具保护。